BOOK 2: The Prototypes

24th March-7th APRIL: D1 and D2 are born amidst lockdown challenges: A tale with Pictures

The MS Teams group is created.

24th March: 11:50: From Navakant Bhat (A chair who cannot give up): “Columbia Open Source Ventilator”

24th March: 11:50: From Navakant Bhat (A chair who cannot give up): “Columbia Open Source Ventilator”

23rd to 27th March its an agonizing wait. We need to get COVID passes!

While KAS is putting together the electricals, on the pneumatics front the team is worrying about getting a regulator that will bring pressure down from 4000 millibar to 40 millibar levels. While there are many, many regulators available in CeNSE, the gas pressures at which the team works is about 2000 millibar delivery pressure to the equipment it uses in the clean room. In this case the system, the human lung, needs a delivery pressure of 40 millibar!! 10 millibar more could be fatal. The team does not have such regulators or even worse pressure sensors that measure such low pressures ACCURATELY. Important enough to repeat, “pressure sensors that measure such pressures accurately as if the sensor is wrong, the system could kill instead of cure.

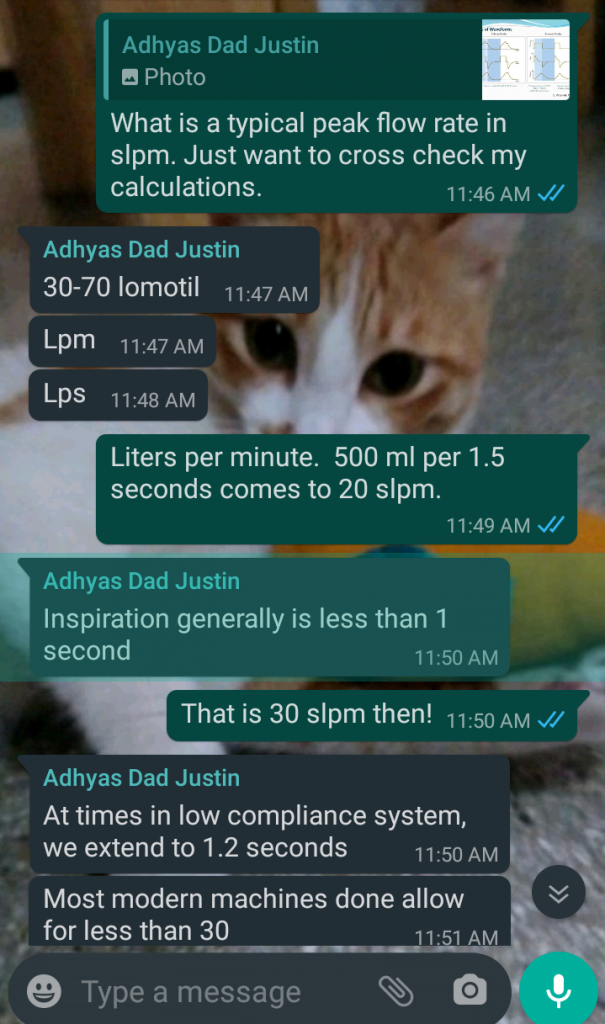

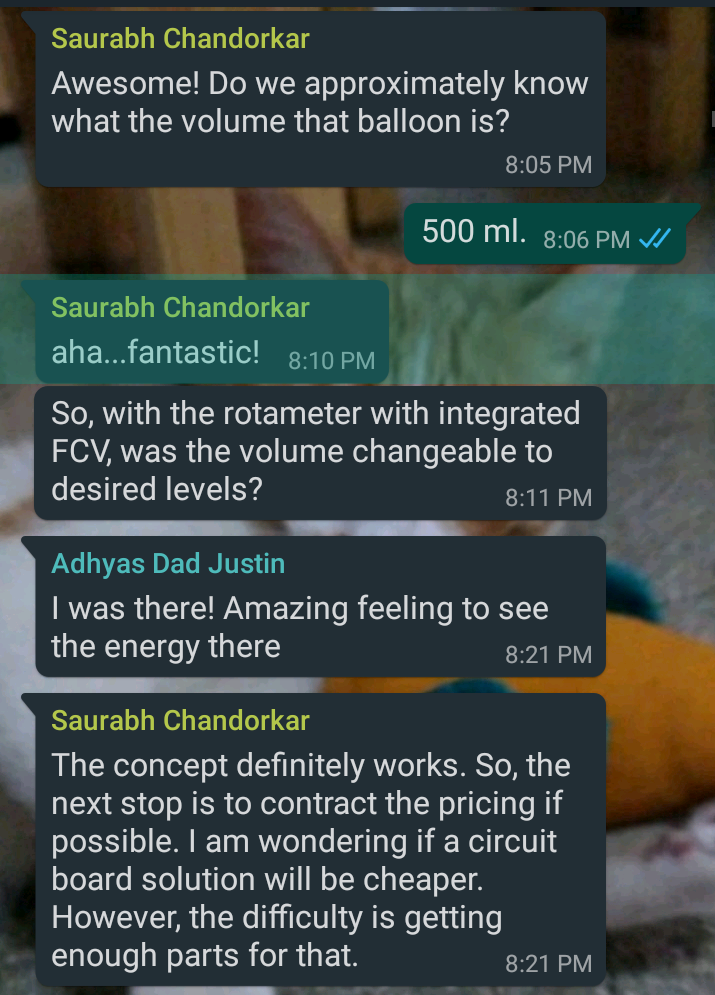

The human body is an amazingly delicate system. Vasu, a professor at CeNSE has worked on making many CVD reactors including the very complicated gas system that involving 30 plus gases at CeNSE in IISc. This one rattles him. (March 28th: He sticks an Ambu bag into his mouth and presses it. His body recoils. That is when he understands how our body might react if air is pushed in when it is not asking for it. Ventilator synchronization requirements sink in. Nothing can replace experience. One has to be careful, he realizes, before saying that one has made a ventilator). We breathe in large volumes of air, 500-1500 ml per breath in 1 second. This translates to a flow rate of 30-90 (std) liters per minute of air!!!!!

The human body is an amazingly delicate system. Vasu, a professor at CeNSE has worked on making many CVD reactors including the very complicated gas system that involving 30 plus gases at CeNSE in IISc. This one rattles him. (March 28th: He sticks an Ambu bag into his mouth and presses it. His body recoils. That is when he understands how our body might react if air is pushed in when it is not asking for it. Ventilator synchronization requirements sink in. Nothing can replace experience. One has to be careful, he realizes, before saying that one has made a ventilator). We breathe in large volumes of air, 500-1500 ml per breath in 1 second. This translates to a flow rate of 30-90 (std) liters per minute of air!!!!!

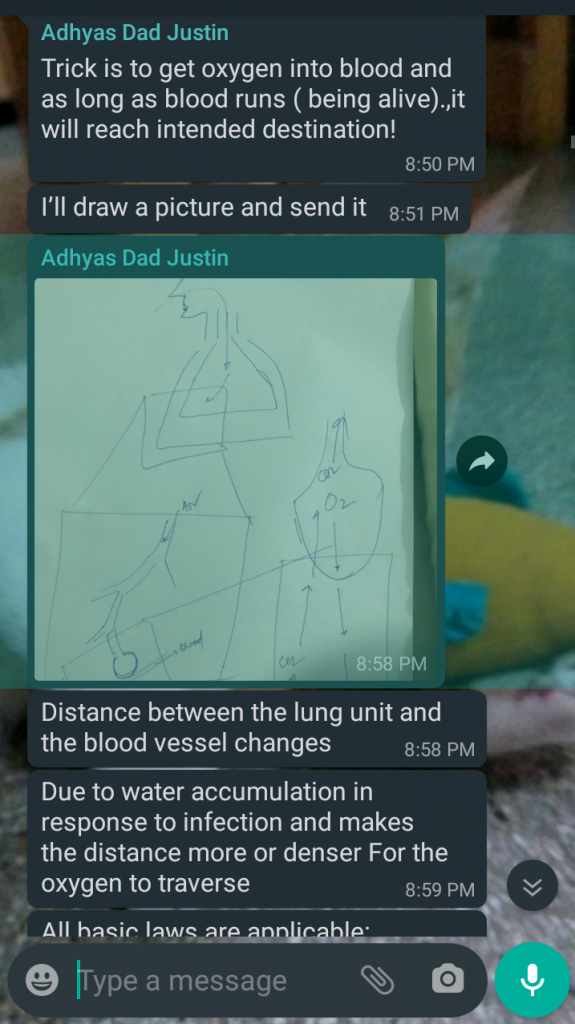

This flow rate has to be supplied at a very low pressure drop. This is like supplying a large current at a very small voltage drop. Resistances have to be very low. A system that is built, needs to ramp up from 0 to the delivery pressure and flow rate within milliseconds (WhatsApp message from Dr. Justin on March 26 “you have 0.2 seconds!”….Right Doc whatever you say) - after all a breath is only 1-2 seconds long – and yet be tightly controlled to prevent overshooting the set value. If it overshot, well, you can guess what would happen. Thus, the team is obviously very concerned. Think control, think microprocessor and think microprocessor…well ventilation is on its way to being replace with a ventilator in thought.

Is the team still thinking of a ventilator the way it looks today. Probably not.

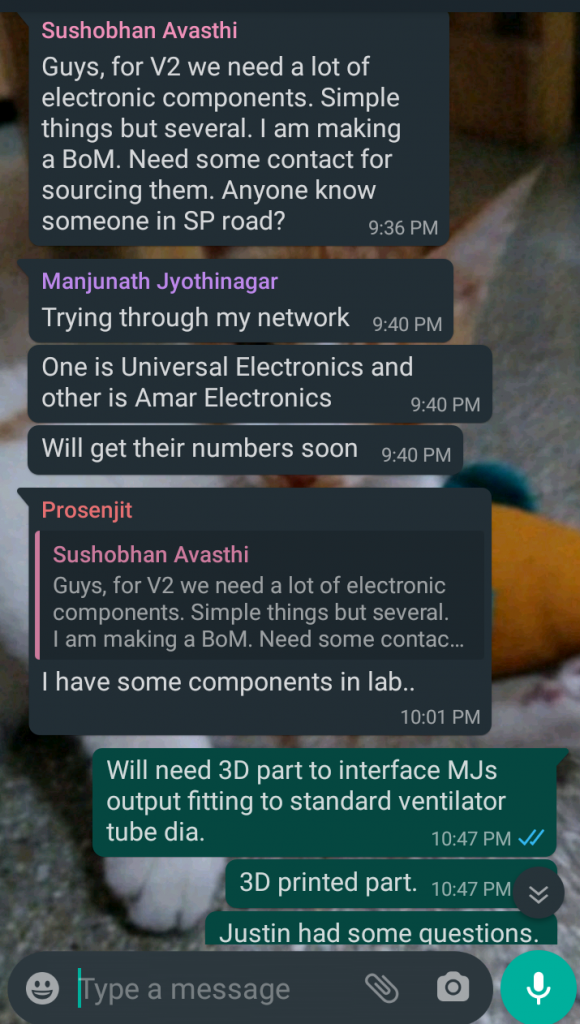

The BOM is getting bigger. Sushobhan Avasthi, a tall lanky young assistant professor who goes climbing in the Himalayas, has a spouse who works harder than he does on financial strategies and a 3 year old at home, gets into the act. Does he know how he is going to get sucked in? (Note: Tracing back, this post from Sushobhan is the genesis of D2) Letting him loose is like watching a Formula 1 car take off. He will be the lynch pin of the D2 development.

Is the team still thinking of a ventilator the way it looks today. Probably not.

The BOM is getting bigger. Sushobhan Avasthi, a tall lanky young assistant professor who goes climbing in the Himalayas, has a spouse who works harder than he does on financial strategies and a 3 year old at home, gets into the act. Does he know how he is going to get sucked in? (Note: Tracing back, this post from Sushobhan is the genesis of D2) Letting him loose is like watching a Formula 1 car take off. He will be the lynch pin of the D2 development.

It does not end there. At 12:31, 28 minutes later, Saurabh Chandorkar jumps in. He is CeNSE’s “youngest” faculty member, a man with a beautiful smile, who likes munching on chips, has an even busier software engineer as a spouse, 2 kids and an elderly mother. He has decided he will not leave his apartment till the COVID risk is past. He is the code master. The controller of the rings. The code is the heart of a ventilator.

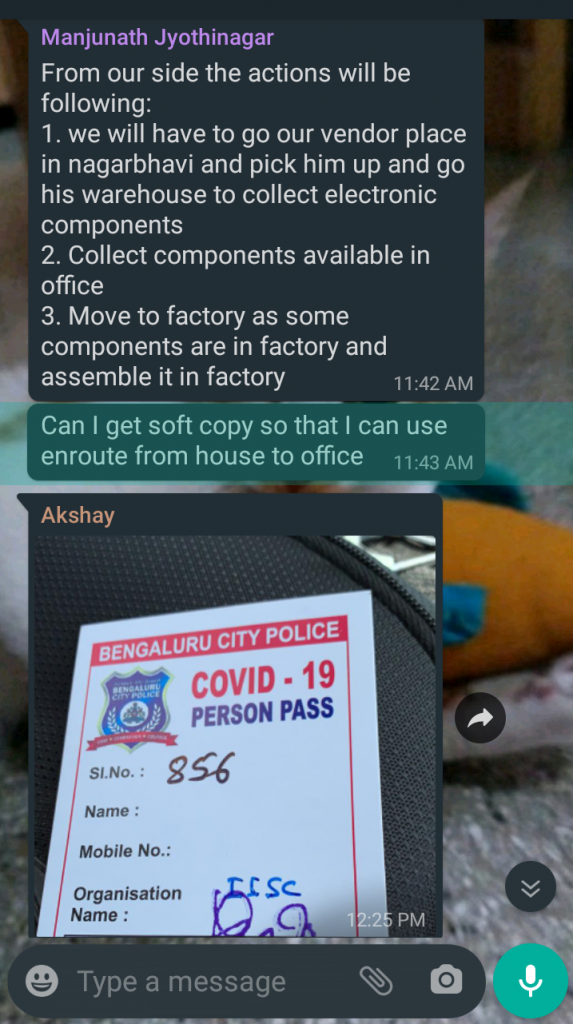

In the meanwhile, Rudra Pratap, the Deputy Director of the Institute and Akshay Naik are pushing to get the team COVID passes so that they can travel. Dr. Justin, a doctor of the useful kind is in the meanwhile giving the doctors of the useless kind a crash course the human breathing apparatus.

In the meanwhile, Rudra Pratap, the Deputy Director of the Institute and Akshay Naik are pushing to get the team COVID passes so that they can travel. Dr. Justin, a doctor of the useful kind is in the meanwhile giving the doctors of the useless kind a crash course the human breathing apparatus.

Justin is one cool doctor. He and his family – a dentist spouse and a swimmer daughter – have driven all the way from Europe to India by road. He bikes, as in bicycles, to work every day. The team is trying to convert his description of the lung in medical language into engineering language – Sushobhan and Saurabh are electronics engineers. They for the purposes of control covert it into an RC- Resistance-capacitance circuit! It will work eventually.

Still no passes… Its frustrating. Manjunath and his team at KAS Technologies have in the meanwhile put the BOM together and the locations from where they can be sourced even during the lockdown. MJ as he is known is a first generation entrepreneur and was responsible for installing the complex gas system at CeNSE. His company is into design, manufacturing and installation of high purity gas systems such as the ones required in electronics manufacturing.With 2 kinds, a doctor for a spouse and a dog, MJ is always used to working 25/8. He suddenly has free time due to the lockdown. “Take a vacation man, oh! no wait! don’t do that, we need you to make our designs.”

Still no passes… Its frustrating. Manjunath and his team at KAS Technologies have in the meanwhile put the BOM together and the locations from where they can be sourced even during the lockdown. MJ as he is known is a first generation entrepreneur and was responsible for installing the complex gas system at CeNSE. His company is into design, manufacturing and installation of high purity gas systems such as the ones required in electronics manufacturing.With 2 kinds, a doctor for a spouse and a dog, MJ is always used to working 25/8. He suddenly has free time due to the lockdown. “Take a vacation man, oh! no wait! don’t do that, we need you to make our designs.”

The passes arrive at last on the 27th of March at 12:25 pm.

Note the time.

The gun has cracked. The sprint has started….the team has started moving all over Bengaluru with their passes to assemble items. By 18:00 hrs in the evening the items have been assembled at KAS Technologies in Doddabellapur

As D1 is being assembled, Sushobhan has started work on D2. It will need even more parts than D1.

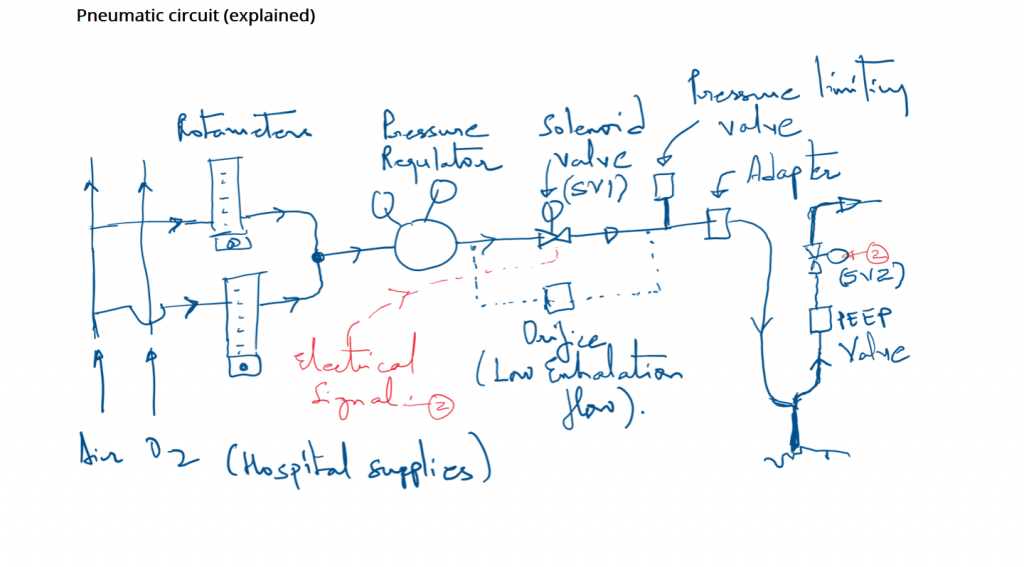

(Note: D1 is a simple pressure pulse ventilation system. It uses a single solenoid, an electrically actuated valve, to pulse, a regulator to control pressure and two rotameters to control flow. It can be assembled without much electronics. Sushobhan however feels that more features can be enabled with a single proportional valve. Much to Vasu’s discomfort, not voiced publicly, the team is moving towards making a ventilator. However, he does not interfere. This is the CeNSE and IISc way. Give people the freedom to do what they want to do. Vasu knows that if D2 is enabled, D1 will any ways get done as it is a much simpler system)

(Note: D1 is a simple pressure pulse ventilation system. It uses a single solenoid, an electrically actuated valve, to pulse, a regulator to control pressure and two rotameters to control flow. It can be assembled without much electronics. Sushobhan however feels that more features can be enabled with a single proportional valve. Much to Vasu’s discomfort, not voiced publicly, the team is moving towards making a ventilator. However, he does not interfere. This is the CeNSE and IISc way. Give people the freedom to do what they want to do. Vasu knows that if D2 is enabled, D1 will any ways get done as it is a much simpler system)

The important point to note is that the need for a 3D printer is now felt when different pneumatic components are to be brought together. The 3D printer will turn out to be a critical capability without which in hindsight it would have been impossible to put the prototype together.

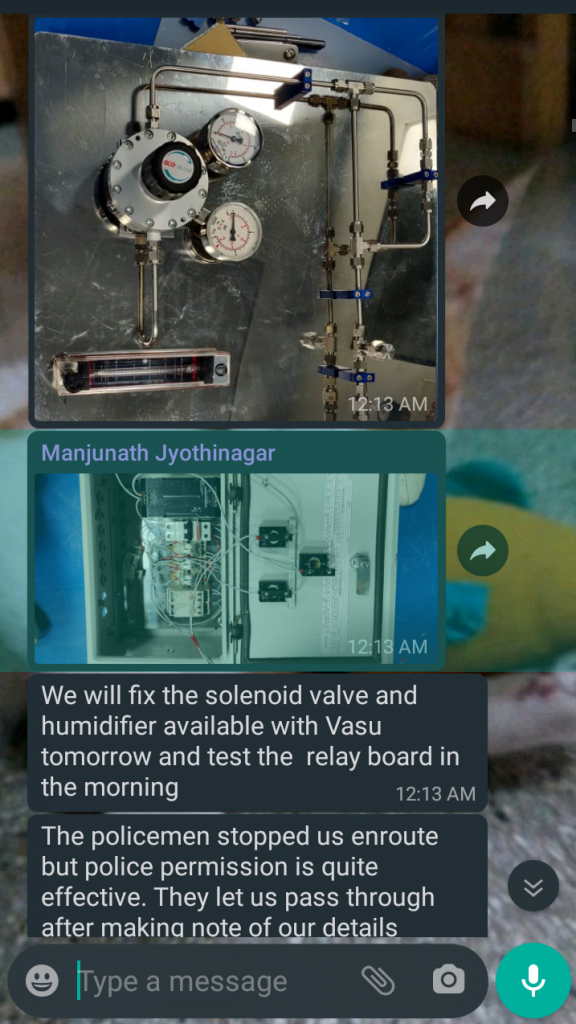

28th March 12:23 am (24 Hrs later): Industry works it magic. The team at KAS technologies has put together the first version of the prototype within 12 hours, pneumatics and electricals, of having received the pass. Sagar Khot a key engineer is actually a pharmacy graduate, who has been working with Manjunath since the CeNSE days on gas piping! His family and wife are in Mumbai amidst the raging pandemic there while he is here in Bengaluru putting together a ventilation system. Sagar is a wizard with gas connections and can identify threads and sizes with the glance of an eye.

A low pressure regulator, that can go down to 40 mbar and a solenoid are still elusive. Students sitting in Delhi, Mysore and Bengaluru are scouting every possible online mart for vendors. Then, bingo, there is a supplier in Bengaluru of Vanaz regulators, low pressure regulators meant for cooking gas purposes (and also hospital services). The regulator is half way across town on one side. The solenoid on the other side with Mr. Suresh from Hydro Pneo Vacuum technologies.

A low pressure regulator, that can go down to 40 mbar and a solenoid are still elusive. Students sitting in Delhi, Mysore and Bengaluru are scouting every possible online mart for vendors. Then, bingo, there is a supplier in Bengaluru of Vanaz regulators, low pressure regulators meant for cooking gas purposes (and also hospital services). The regulator is half way across town on one side. The solenoid on the other side with Mr. Suresh from Hydro Pneo Vacuum technologies.

Over the next few months Mr. Suresh, another first generation entrepreneur, will help the team in various ways by supplying components freely from the stash in his workshop. Following a 40 km around the town ride, through and around barricades, Vasu gets these to CeNSE. (This was at the starting point. As the team will learn later one can do with regulators that can deliver at higher pressures so long as the downstream pneumatics is robust enough to control pressures. However, at the beginning as the team of engineers was beginning to interface with the human body, a delicately balanced mother of all machines, it was very tentative. Thus, it wanted to limit pressures to 40 milli bar.) Meera a free lance architect and is wife is very unhappy and understandably so.

“You are putting the entire family and community at risk,” she says. She has been paranoid (Only the Paranoid Survive, as Andy Grove the INTEL CEO said) and had bought sanitizers in late Jan itself as the pandemic was breaking out in China. Lost in his academic world, Vasu was shaken to become conscious of this new problem by her to a large extent.

March 29: 12:00 pm (49 hours from the pass): The team assembles in CeNSE amidst the lockdown. MJ and Sagar come down with the assembly.

Enter

March 29: 12:00 pm (49 hours from the pass): The team assembles in CeNSE amidst the lockdown. MJ and Sagar come down with the assembly.

Enter

ANKIT RAO AND HARSH(VARDHAN) GUPTA, CeNSE PhD students

It is said that the best place to find an IISc faculty member is in Bengaluru airport. (This of course is expected to change post the pandemic. When and where will they get all their ideas from? It is going to be tough challenge.) What this means is that they have little knowledge of where things are in the lab. It is the student who knows all of this. Running, D1, as it has now come to be called, requires interfacing it with existing equipment in Vasu’s lab to supply gases and measure parameters. The team still does not have sensors. It is lucky that Ankit a PhD student with a chemical engineering degree working on chemical vapor deposition, a small physique, a bright smile and who never says no to anything has stayed back in Bengaluru in spite of the lockdown. He ambles in and helps hook D1 up to his CVD reactor that has sensors mounted on it. More connectors are needed. Harsh, a tall gangly mechanical engineer with a degree in mechatronics and working on micro electro mechanical systems for his PhD offers to help. Over the next few months he will design and 3D print innumerable components, solder electronic boards and help with trouble shooting code. Between them the team has all the expertise required…. Almost. From then on, like a Tom and Jerry show, it’s a Harsh and Ankit show for the next 3 months. They will take over and help design, build, trouble shoot and create the ventilators. Vasu takes a back seat. He knows that the best drivers have taken their place. Its time to sit back and enjoy the race.

March 29th 18:13 hours (54 hours later): D1 is done. It is an exhilarating feeling but there is a long way to go.

March 29th 18:13 hours (54 hours later): D1 is done. It is an exhilarating feeling but there is a long way to go.

As D1 is getting completed Sushobhan Avasthi has gone on a jaunt to get components for what is now called D2. The team has a lucky break. While proportional valves are not available, the student gang has made calls to everyone and sundry. Mr. Kartigeyan at Festo confirms that he has trial proportional valves that the team to could pick up and, not just one but two. It cannot be “Dunzoed,” for a change as it falls outside city limits. (Like 3D printing, Dunzo was another critical component). He zig-zags across the city and comes to CeNSE with a sack full of electronic components. (A solenoid valve is an on-off switch. A proportional valve is a know that allows for better control. But .. it needs a feed back loop).

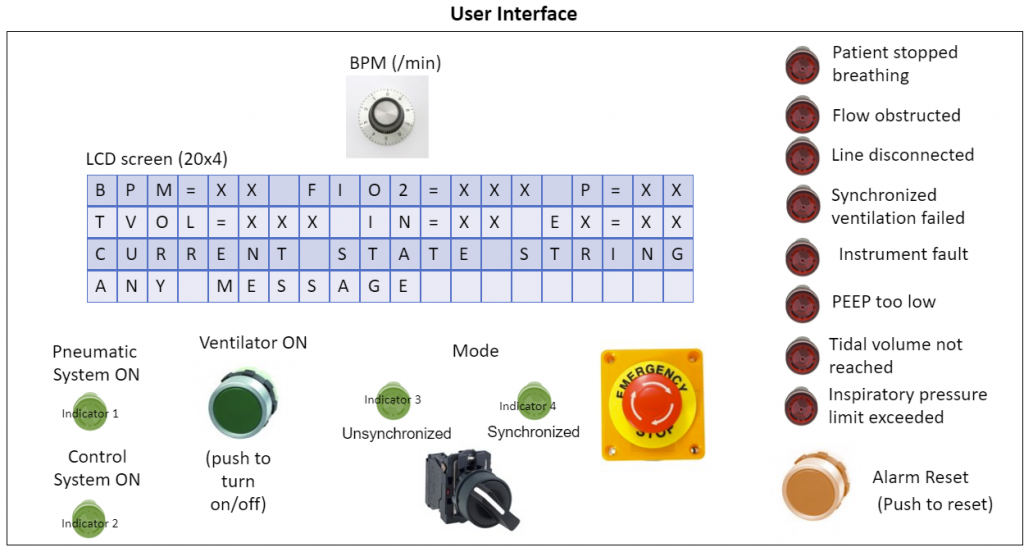

While Sushobhan and Harsha get started with putting the electronic board for D2 together. He plans to do the controls of an Arduino board, while using an LCD screen for a user interface. He has thought through the many alarms that are required and need programming in. Fast forward a bit and you will see his reaction and ours when a new GUI suddenly pops up on the team. A mystery man has been secretly working on it. You can guess why he had to go across-Bangalore to source various components.

While Sushobhan and Harsha get started with putting the electronic board for D2 together. He plans to do the controls of an Arduino board, while using an LCD screen for a user interface. He has thought through the many alarms that are required and need programming in. Fast forward a bit and you will see his reaction and ours when a new GUI suddenly pops up on the team. A mystery man has been secretly working on it. You can guess why he had to go across-Bangalore to source various components.

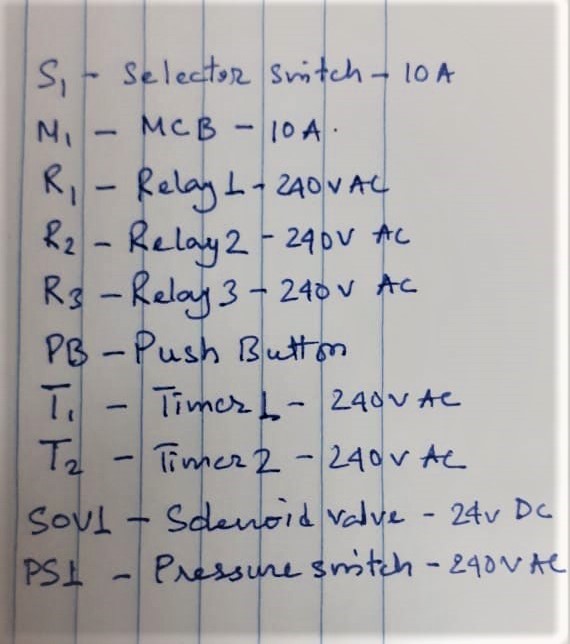

While Arduino will allow for control, the team still needs a board to channel power to the various components of the ventilator. The big box needs to be replaced. It is OK for a prototype but not for a product. Vasu calls his good friend G. Narayanan, a professor and Chair of the electrical engineering department to come and take a look. GN, as he is fondly called, in spite of all his business, puts the team in touch with Kapil his student in Delhi. Working with Sushobhan, they help design the boards that then needs to get manufactured.

30th March: While the team has tested D1 on a balloon, they still need a test lung and an exhaust valve called a PEEP valve that can maintain pressure during exhalation and prevent the lung from collapsing. MJ and Vasu make the trip to Manipal hospital where Justin helps them with these components. Back to CeNSE the team tests D1 on this test lung.

The team has now hooked up the ventilator to a data acquisition unit (DAQ) to monitor pressure profiles.

They don’t like what they see.

The profiles should have looked square and not triangular. (Note: 27th July: In hindsight these profiles may have been that bad after all for an emergency ventilator. The team at that point was looking for a square looking wave. As this article is being written, the team has gone back to evaluating D1 for the original intent, a cost-effective CPAP or BPAP instrument). When we try to breathe, and we do so in 1 second, we are presented with a reservoir of air at atmospheric pressure. Imagine if the pressure went up slowly to atmospheric pressure and only then you were able to breathe. You would be left gasping every time. Not acceptable. Similarly, in a ventilator, the pressure needs to go up quickly, within 200 milli seconds and not rise up slowly. Time to look at D2. A set up that will allow imposing a high potential that will allow charge to build up quickly and then control it to specific levels…..

30th of March 17:07:

KAS technologies works its magic again. The D2 pneumatics are ready! Wait not yet. Its not done till its done.

KAS technologies works its magic again. The D2 pneumatics are ready! Wait not yet. Its not done till its done.

D2 works on a proportional valve which needs a feedback from a sensor for pressure and flow rate control. Sensors - our world of IOT is going to be full of them – and that too accurate, calibrated and ones that you can trust, are not easy to come by at regular times, let alone in a lockdown.

While Sushobhan has ordered pressure sensors they are stuck in Mumbai airport where the warehouse has apparently been quarantined. Some pressure sensors are available in Bangalore and at quiet some distance. In the meanwhile, there is a team in NAL that is also developing such pressure sensors. However, this is the testing phase. Sensors always go bad. The team needs a source of sensors and somebody who can keep fixing them in case they go bad. Pandian and the CeNSE packaging lab come to the rescue. Professors Naik, Bhat and Pratap have been developing pressure sensors in CeNSE, but they are meant for higher ranges above 100 millibar gauge. Ventilators require sensors in the 0-100 millibar gauge region. Still the team goes ahead with the intention of testing the control logic. It will be repurposed to control pressure accurately in the range the human body likes it, when the low pressure sensors arrive.

Another parameter that needs to be controlled is flow. Flow sensors that they can use are not easily available.

Saurabh suggests using the age old Bernoulli’s effect to measure flow by detecting pressure drops across a venturi. Ankit gets on the job by pulling out his old chemical engineering textbooks. The team also contacts Prof. Sanjeev Gupta in chemical engineering for his insights as it is a challenging problem. Large flows, 30-90 SLPM, have to be supplied without introducing big resistances in the flow path. (Here again remember we are submerged in this infinite reservoir of fluid that we take for granted around us from which we suck in huge volumes through very large conductance path ways whenever we want it. Its called breathing!) A resistance will once again take you back to a triangular pulse. Not introducing a big resistance will however not cause a large enough pressure drop that can be accurately measured. Using a combination of getting back to the basics of chemical engineering, various venturi designs that are 3D printed and an external calibrated flow rate instrument the team will eventually get to a flow sensor system they are satisfied with in late July.

For the time being to test the D2 concept, Harsha 3D prints out a plastic venturi. The team connects a differential pressure supplied by Pandian across the venturi for flow and another sensor for pressure to provide Saurabh, the code master with a feedback. They test it calibrate it, change the design, reprint it, test it and the iteration goes on. Reliable feedback is very important for closed loop control to work properly. Sushobhan works with Harsha and Ankit to get the electronics hooked up to the pneumatics supplied by KAS and the DAQ.

Another parameter that needs to be controlled is flow. Flow sensors that they can use are not easily available.

Saurabh suggests using the age old Bernoulli’s effect to measure flow by detecting pressure drops across a venturi. Ankit gets on the job by pulling out his old chemical engineering textbooks. The team also contacts Prof. Sanjeev Gupta in chemical engineering for his insights as it is a challenging problem. Large flows, 30-90 SLPM, have to be supplied without introducing big resistances in the flow path. (Here again remember we are submerged in this infinite reservoir of fluid that we take for granted around us from which we suck in huge volumes through very large conductance path ways whenever we want it. Its called breathing!) A resistance will once again take you back to a triangular pulse. Not introducing a big resistance will however not cause a large enough pressure drop that can be accurately measured. Using a combination of getting back to the basics of chemical engineering, various venturi designs that are 3D printed and an external calibrated flow rate instrument the team will eventually get to a flow sensor system they are satisfied with in late July.

For the time being to test the D2 concept, Harsha 3D prints out a plastic venturi. The team connects a differential pressure supplied by Pandian across the venturi for flow and another sensor for pressure to provide Saurabh, the code master with a feedback. They test it calibrate it, change the design, reprint it, test it and the iteration goes on. Reliable feedback is very important for closed loop control to work properly. Sushobhan works with Harsha and Ankit to get the electronics hooked up to the pneumatics supplied by KAS and the DAQ.

7 days of non-stop activity and

7th April 20:23 pm: D2 is born…

A small rewind…

April 5th 20:23.

While the nuts and bolts of D2 were being put in place, in parallel Prosenjit Sen, a Professor at CeNSE was working on the GUI. A quiet team member, Prosenjit’s style is to listen and at the end give an opinion in a line or two. It would capture the essence. In this inimitable style, he also dished out the GUI on the 5th of April to everyone’s amazement. That is when Vasu makes up his mind to recount this story. The Doctor’s “Wow” sums it all up.