Prof. Rudra Pratap's Research Group

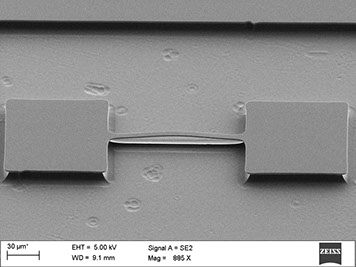

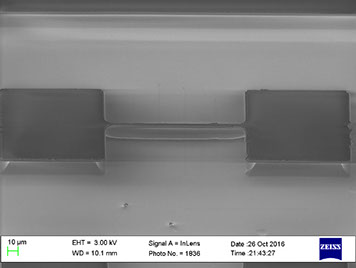

The performance of dynamic MEMS devices, such as 1D and 2D resonators, microphones, gyroscopes, and ultrasound transducers, is highly dependent on the natural frequency and quality factor of the vibrating micro-mechanical structure. Residual stresses are invariably present in MEMS structures. They are induced during the deposition of thin films and during the fabrication process . We study the effect of residual stress present in MEMS structures based on their response to periodic excitations and aim to exploit it for potential applications (e.g. measurement of material properties and sensing). The figures below show images of fixed-fixed beams fabricated from PECVD deposited silicon carbide and silicon nitride thin films. Measurements were carried out on these structures to find their natural frequencies and the plots are presented below.

Fixed-fixed beam fabricated from silicon carbide films deposited by PECVD. The beam is buckled due to presence of compressively residual stress in the thin

Fixed-fixed beam fabricated from silicon nitride films deposited by PECVD. There is tensile residual stress present in the beam.

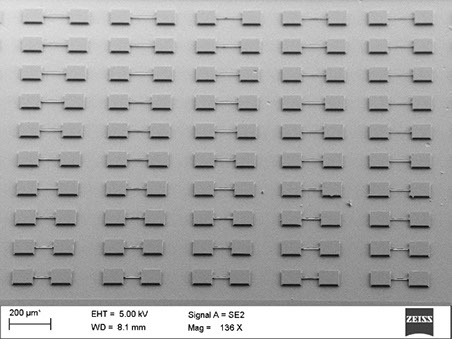

Array of fixed-fixed beams fabricated and used in the study

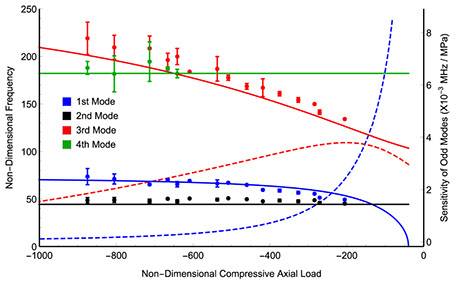

Non-dimensional frequency (first four modes) vs. Non-dimensional axial load parameter plot for compressive residual stress carrying buckled PECVD-SiCx beams. Solid-lines and points show the analytical prediction and measured natural frequencies respectively and the dashed lines show the sensitivity of frequency to residual stress.

MEMS Lab, Centre for Nano Science and Engineering, Indian Institute of Science. Bangalore-560012

Phone: +91 (80) 2293 3250, +91 (80) 2360 8659 Fax: +91 (80) 2360 1648 Email: pratap@iisc.ac.in, memslab@iisc.ac.in