COVID-19 related work with societal impact

During the COVID-19 pandemic Science and Technology are playing a crucial role in keeping our society functional. As part of incident management and response, CeNSE mustered all its resources and initiated multiple projects to address the issues arising out of the current global public health crisis. The results of these innovations will have a long-lasting impact, even beyond COVID-19, on building a resilient society.

Imaging of droplet spread in a room that is critical to understanding how the virus laden aerosol spreads in confined spaces: This experiment was in collaboration with colleagues (experimentalists and theorists) at the Department of Physics, IISc, Princeton University and University of Toronto. A business plan along these lines has been formulated and submitted to the Society for Innovation and Development, IISc. Currently the group is trying to make connections with possible end users and stakeholders to fine tune the product further.

Imaging of droplet spread in a room that is critical to understanding how the virus laden aerosol spreads in confined spaces: This experiment was in collaboration with colleagues (experimentalists and theorists) at the Department of Physics, IISc, Princeton University and University of Toronto. A business plan along these lines has been formulated and submitted to the Society for Innovation and Development, IISc. Currently the group is trying to make connections with possible end users and stakeholders to fine tune the product further.

(Principal Investigator: Ambarish Ghosh, CeNSE, IISc)

- Mask Testing: As the number of COVID cases surged around the world, it was quite evident that there would be a severe shortage of N95 masks which are critical personal protective equipment (PPE) for health care workers. The shortage of these masks was further compounded by flooding of the market with fake and substandard N95 masks. To address these issues, researchers in CeNSE have developed a home-made setup to test the masks. The setup was initially built to test whether the efficiency of the N95 masks reduces with repeated usage, but is now also used to test the quality of masks that are available in the market.

The setup can test two aspects of the masks:

a) particle filtration efficiency: measures how effectively the masks filter out particles of various sizes.

b) breathing resistance: measures the pressure drop across the mask and is a measure of how easy it is to breathe through the masks.

With this system, CeNSE has been able to help multiple faculty members from IISc who are keen on making materials for N95 masks, doctors with ideas to develop powered air-purifying respirators, and vendors who wanted to test imported N95 masks. Some indigenous N95 mask manufactures also got their masks tested with our system before sending it out for certification.

(Principal Investigator: Akshay Naik, CeNSE, IISc)

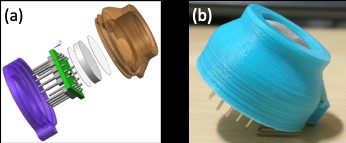

3D printed valves for split use of ventilators: In the wake of the COVID-19 crisis that has resulted in widespread ventilator shortages, this device was designed to enable multiple patients to be ventilated with one intensive care ventilator. The first of these splitter valves fabricated at CeNSE has been delivered to Manipal Hospitals and tested there with simulation lungs (video of the same can be found here:

3D printed valves for split use of ventilators: In the wake of the COVID-19 crisis that has resulted in widespread ventilator shortages, this device was designed to enable multiple patients to be ventilated with one intensive care ventilator. The first of these splitter valves fabricated at CeNSE has been delivered to Manipal Hospitals and tested there with simulation lungs (video of the same can be found here:

(Principal Investigator: Akshay Naik, CeNSE, IISc)

Sub-INR 50,000 Ventilator: Starting with the aim of creating an industrial scale “ventilation solution”- along the lines of the CeNSE clean room gas supply system, but to supply air and oxygen mixtures as opposed to a ventilator – a team of about 40 researchers coordinated by CeNSE have developed 4 versions of various ventilator prototypes. These were developed in coordination with two industry partners and Manipal Hospitals. The last of these prototypes is currently being assembled and is expected to undergo certification within the next one month. The details of this mammoth effort can be obtained from

Sub-INR 50,000 Ventilator: Starting with the aim of creating an industrial scale “ventilation solution”- along the lines of the CeNSE clean room gas supply system, but to supply air and oxygen mixtures as opposed to a ventilator – a team of about 40 researchers coordinated by CeNSE have developed 4 versions of various ventilator prototypes. These were developed in coordination with two industry partners and Manipal Hospitals. The last of these prototypes is currently being assembled and is expected to undergo certification within the next one month. The details of this mammoth effort can be obtained from

http://www.cense.iisc.ac.in/ventilator/.

(Contact: Srinivasan Raghavan, CeNSE, IISc)

Pressure sensors for ventilators: A Pressure Sensor is the heart of the ventilator as it constantly provides feedback on how the person is responding to the support, which decides how the support is adjusted. It was decided that the very low-pressure aerospace-grade MEMS pressure sensors would be reconfigured to cater to the requirements of Project Praana (another ventilator effort at IISc - https://covid19.iisc.ac.in/project-pranaa-voluntary-ventilator-prototype-design-effort/) and also the CeNSE ventilator team. These MEMS very low-pressure sensors were initially designed and fabricated at the National Nano Fabrication Facility, CeNSE. The same were reconfigured with electronics, tested, calibrated, and packaged for two different pressure ranges in consultation with the Project Praana team. Ultimately, three numbers of these pressure sensor prototypes were given to Project Praana for trials. Based on the feedback, these sensors can be productised.

Pressure sensors for ventilators: A Pressure Sensor is the heart of the ventilator as it constantly provides feedback on how the person is responding to the support, which decides how the support is adjusted. It was decided that the very low-pressure aerospace-grade MEMS pressure sensors would be reconfigured to cater to the requirements of Project Praana (another ventilator effort at IISc - https://covid19.iisc.ac.in/project-pranaa-voluntary-ventilator-prototype-design-effort/) and also the CeNSE ventilator team. These MEMS very low-pressure sensors were initially designed and fabricated at the National Nano Fabrication Facility, CeNSE. The same were reconfigured with electronics, tested, calibrated, and packaged for two different pressure ranges in consultation with the Project Praana team. Ultimately, three numbers of these pressure sensor prototypes were given to Project Praana for trials. Based on the feedback, these sensors can be productised.

(Principal Investigator: MM Nayak, CeNSE, IISc)

Oxygen sensors for ventilators: The efforts initiated at IISc for the development of a medical grade ventilator required a crucial sensor to be integrated – the Oxygen sensor. This sensor would enable exact measurement of Oxygen concentration in the mixture of 100% Oxygen gas and air, which needs to be carefully mixed in the ventilator, depending on the patient’s condition. The gas sensors team at CeNSE had been working on a range of chemi-resistive gas sensors over the last decade, including Oxygen sensor for monitoring oxygen depletion. However, the oxygen depletion sensor was calibrated and developed to measure Oxygen concentrations in the range of 0 to 25%. In contrast, for ventilator application, the requirement was to measure Oxygen in the range of 20% to 100%. This required the re-purposing of Oxygen depletion sensor and re-calibrating it for ventilator application. Through custom packaging of chips using a 3D printer, and extensive characterization of sensor dice, a few prototypes of Oxygen sensors were delivered in record time. With the successful development of Oxygen sensor for ventilators, several ventilator manufacturers have shown interest in sourcing these sensors, based on the technology developed at CeNSE. At present, efforts have been initiated to spin-off a start-up from CeNSE to commercialize this technology and scale-up the production of these sensors.

Oxygen sensors for ventilators: The efforts initiated at IISc for the development of a medical grade ventilator required a crucial sensor to be integrated – the Oxygen sensor. This sensor would enable exact measurement of Oxygen concentration in the mixture of 100% Oxygen gas and air, which needs to be carefully mixed in the ventilator, depending on the patient’s condition. The gas sensors team at CeNSE had been working on a range of chemi-resistive gas sensors over the last decade, including Oxygen sensor for monitoring oxygen depletion. However, the oxygen depletion sensor was calibrated and developed to measure Oxygen concentrations in the range of 0 to 25%. In contrast, for ventilator application, the requirement was to measure Oxygen in the range of 20% to 100%. This required the re-purposing of Oxygen depletion sensor and re-calibrating it for ventilator application. Through custom packaging of chips using a 3D printer, and extensive characterization of sensor dice, a few prototypes of Oxygen sensors were delivered in record time. With the successful development of Oxygen sensor for ventilators, several ventilator manufacturers have shown interest in sourcing these sensors, based on the technology developed at CeNSE. At present, efforts have been initiated to spin-off a start-up from CeNSE to commercialize this technology and scale-up the production of these sensors.

(Principal Investigator: Navakanta Bhat, CeNSE, IISc)

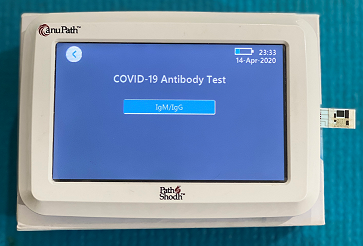

Rapid antibody and antigen tests for COVID: PathShodh Healthcare, the start-up from CeNSE founded by Prof. Navakanta Bhat and Dr Vinay Kumar, is developing a unique diagnostics solution for COVID-19. In particular, PathShodh’s lab-on-palm device anuPath is being re-purposed for both rapid antibody test and rapid antigen test, using electrochemical sensing technology.

Rapid antibody and antigen tests for COVID: PathShodh Healthcare, the start-up from CeNSE founded by Prof. Navakanta Bhat and Dr Vinay Kumar, is developing a unique diagnostics solution for COVID-19. In particular, PathShodh’s lab-on-palm device anuPath is being re-purposed for both rapid antibody test and rapid antigen test, using electrochemical sensing technology.

The commercially available rapid antibody tests are based on lateral flow ELISA technique, analogous to pregnancy testing kits. In contrast, PathShodh’s solution will leverage disposable screen-printed electrodes, for rapid and accurate results. PathShodh has received funding from CAWACH, a DST program, to develop and deploy this product in the market, after due validation and certification over the next few months. Simultaneously, PathShodh is also developing a rapid antigen test, for nasal/oral swab samples, using the same platform. The company has received funding from BIRAC to validate and scale-up production for the rapid antigen testing technology. In summary, PathShodh plans to offer a unique diagnostics solution for COVID-19, for both rapid antibody and rapid antigen test on a single platform.

(Contact: PathShodh Healthcare Pvt. Ltd.)

- Sanitizer for use across the Institute: Just as the whole Institute was going into a lockdown around mid-March, a team of researchers prepared and supplied sanitizer to the entire campus. These bottles have been primarily issued to security personnel at all the entrances to the campus, and to service providers at critical places that have been kept open to serve the needs of campus residents, and students who couldn’t go back to their homes.

(Contact: Savitha P, CeNSE, IISc)