To make the photovoltaic (PV) technology competitive with traditional fossil fuel combustion, cost of the existing photovoltaic systems needs to be reduced by at least another 60%. One way to achieve this is to improve the power conversion efficiency and/or reduce fabrication costs of the state-of-the-art equipment. Historically, the crystalline Silicon (Si) solar cell has been the technology of choice because it had the most success in making PV more affordable. However, going forward there seems to be little room for improvement in conventional Si PV. The efficiency of conventional Si solar cells has stagnated around 25% and the fabrication costs are limited by the high costs of ultrapure crystalline silicon. The goal of the solar cell research at CeNSE is to look beyond the current silicon technology and develop next generation solar PV technology that can boast of substantially higher efficiencies at significantly reduced costs.

Perovskite-like Solar Cells

Figure 1 : The thin-film perovskite cell structure

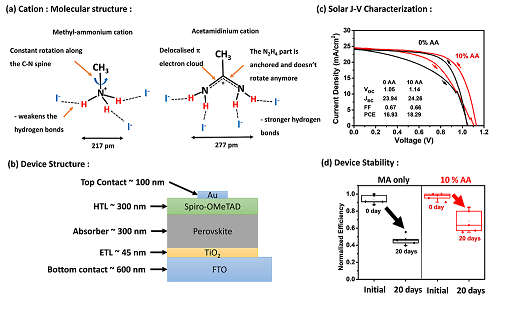

Methylammonium lead trihalide (MAPbI3) perovskite solar cells are a new class of thin-film photovoltaic devices, discovered just 7 years ago, that have already shown exceptional performance (25.3% compared to the current commercially available silicon cells). However, the MAPbI3 technology still faces a significant challenge which is instability in the presence of moisture. From a structural point of view, this instability stems from the weak bonding between the organic cation (methyl-ammonium) and the tetrahedral inorganic cage ( PbI64- ) in the perovskite crystal (I4/mcm). At CeNSE we are trying to solve this problem by adding novel organic cations which are intrinsically more stable than methyl-ammonium. Addition of 10% Acetamidinium (AA) cation (figure 2a) in MAPbI3 yielded solar cells which are more environmentally stable than the reference MAPbI3 cells (figure 2d): ~18% efficient AA substituted cells maintained 75% of their initial stability after 20 days as compared to MAPbI3 cells retaining only 40% of their efficiency in the same time frame.

Figure 2: (a) Molecular structure of methyl-ammonium and acetamidinium cation, (b) Device structure, and (c) J-V Characterization and (d) stability of 0-10% AA devices

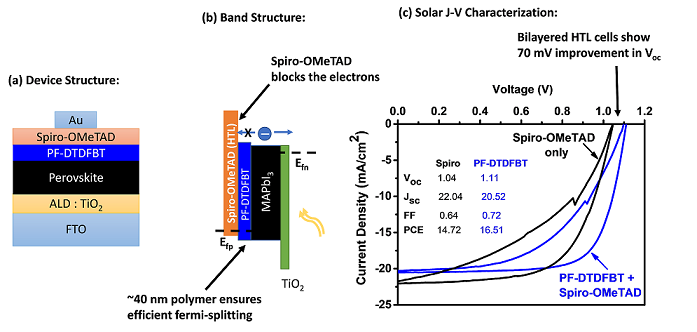

Another parameter of perovskite solar cells where there is scope for improvement is its open-circuit voltage ( Voc ). We, at CeNSE, are trying to increase the Voc by increasing the fermi-splitting in the perovskite. This is achieved by using polymer-based band-matched transport layers. The PF-DTDFBT/Spiro-OMeTAD bilayer HTL devices (better band matching) yielded a higher Voc: 1.11 V, compared to the 1.04 V Voc of the Spiro-OMeTAD only devices.

Figure 3: (a) Device structure (b) Band structure and (c) J-V Characterization of polymer: Spiro-OMeTAD bilayer HTL perovskite solar cells

Other similar projects:

• Integration of novel graphene/polymer encapsulating layer (WVTR ~ 10-6 gm/ m2day ) with the perovskite cells to protect them from water/oxygen and improve their environmental stability.

• Searching for lead-free alternatives to MAPbI3 . Using careful DFT calculations backed by experiments we are scanning the materials space for promising solar materials, with the ultimate goal of demonstrating a reliable efficient thin-film solar cell technology.

Silicon / Metal-Oxide Heterojunction cells:

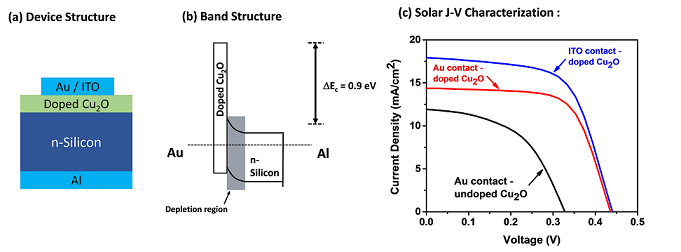

Silicon / metal-oxide heterojunction cells are potential low-cost alternatives of the Silicon p-n homojunction cells. Their (heterojunction) ease of fabrication makes them a favourable candidate for perovskite/silicon tandem cells. In CeNSE, we optimized the Cu2O/Silicon heterojunction to make a solar cell with efficiency increased by 5.23% (figure 4).

Figure 4: (a) Device structure, (b) Band structure, and (c) J-V Characterization of Cu2O /Silicon heterojunction solar cells.

Silicon/Perovskite Tandem Cells

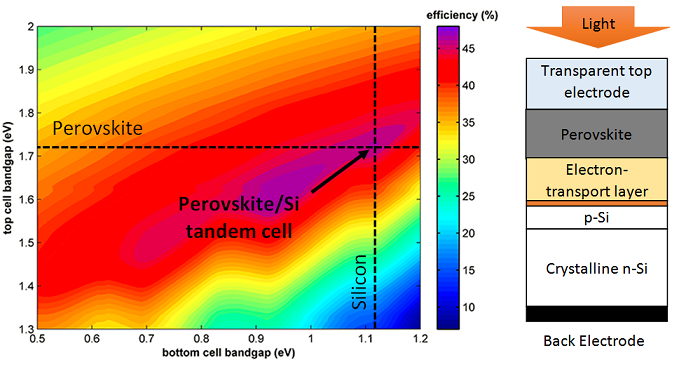

Efficiency of single-material solar cells is limited by thermodynamics in what is called the Shockley-Queisser Limit (SQL). The SQL of perovskite (bandgap = 1.7 eV) and silicon (bandgap = 1.1 eV) cells is only 25% and 30%, respectively. Practical devices usually yield even lower efficiencies –perovskite and silicon solar cells have efficiency of 15-18% and 21-22%, respectively. One way to exceed the SQL is to integrate different absorber materials onto the same device, forming a tandem cell. Given the bandgap of perovskite and silicon, a perovskite/Si tandem cell can theoretically have an efficiency of >40%. Even the realization of a more practical 30% efficient solar device would have tremendous impact on the cost and viability of renewable photovoltaic technology.

Figure 5 : (Left) Maximum theoretical efficiency of a tandem cell with perovskite (bandgap~1.7 eV) as top cell and silicon (bandgap =1.12eV) as the bottom cell is more than 40%. (Right) The perovskite/Silicon tandem cell device structure.

|

Associate Professor |

Visiting Professor |

Associate Professor |